D-sig / D-sig Plus

- Sheets are introduced from the printer – Accurately registered – Automatic control of sheet position

- Cross folding (optional item), for 8 page folding

- Scoring of the spine fold line

- Longitudinal folding incorporating

5. Pressing of the longitudinal fold to assure a compact and square book spine

6. Signature make up on the saddle by the insertion of folded sheets – The completed signature then moves on to the sewing stage.

7. D-Sew: thread sewing machine.

Modular machine for folding, collating and saddle inserting. An interface between digital printing and traditional book binding equipment.

- Max. Speed: 120 m/min.

A4 format: 300 A4/min — A3 format: 200 A3/min

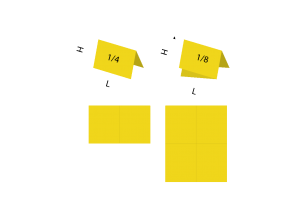

D-sig 1/4

Max. in cm: L42 – H31

Min. in cm: L15 – H10

D-sig Plus 1/8

Max. in cm: L30 – H23

Min. in cm: L15 – H10

D-Buckle: cross fold (8-page fold adjustment)

D-Mix: simultaneous processing of b/w and full color sheets

D-Turn: in-line connection with sheet rotation before folding

D-BJC: integrated in-line / off-line (by pass) connection

D-Exit: preparation / realization of folded-only

D-Stitch: connection toa wire stitching machine

Printing:

Sheets are fed directly by the digital printer. It is also possible to feed sheets from:

- a pile feeder

- single-sheet rolls wound up using Digi-Roll system

- cutting systems combined with rolls of continuous printed sheets

Sewing:

D-sig is equipped with:

- a programming panel to introduce job data, i.e. number of sheets required to make up signature and number of signatures required to make up a book block.

- an interface with logic control to connect system to digital printer (machine ready, end of book, etc…)

- controls to operate all sewing machine functions